Welded Wire Mesh Specifications and Information

Welded Wire Mesh Product Description

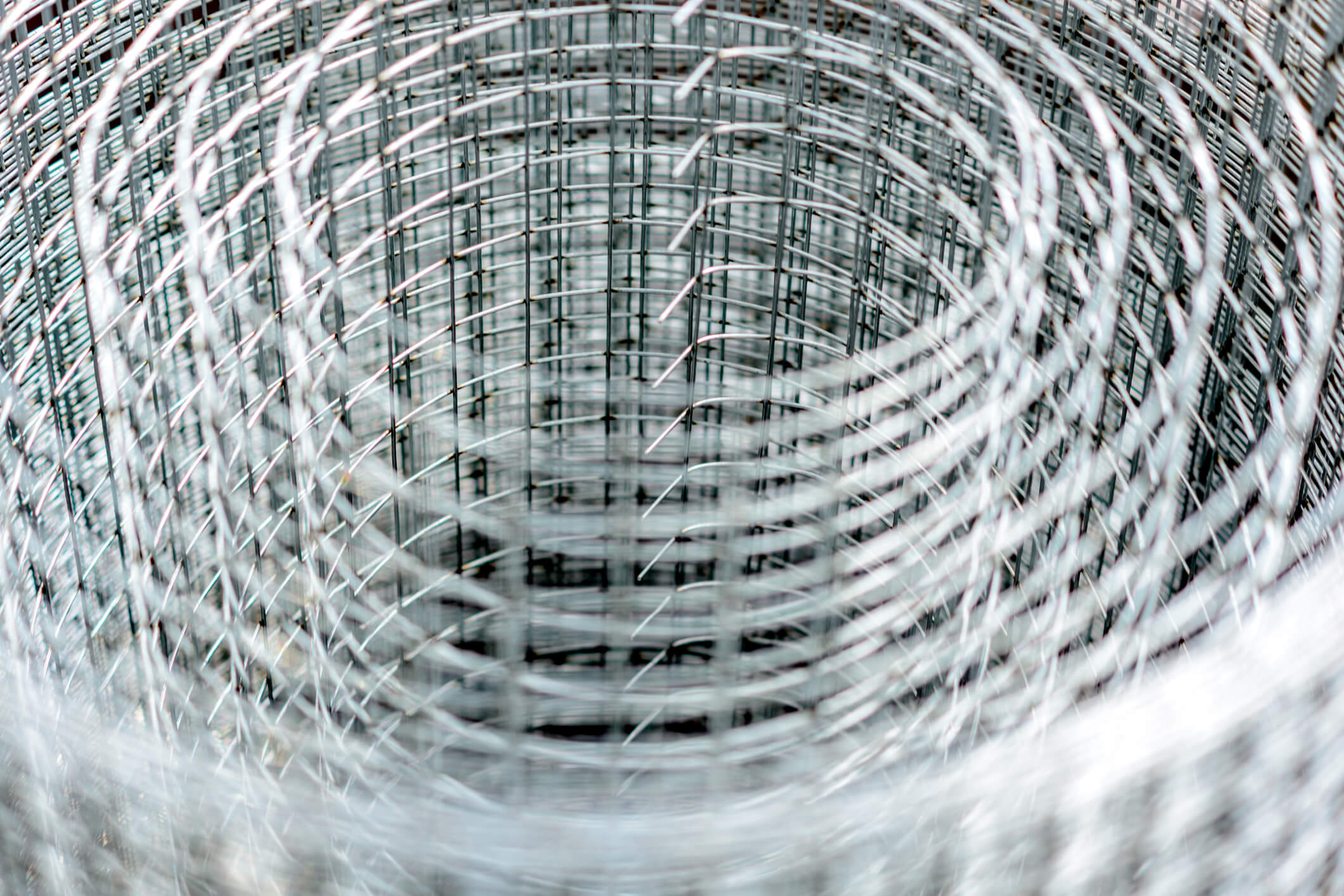

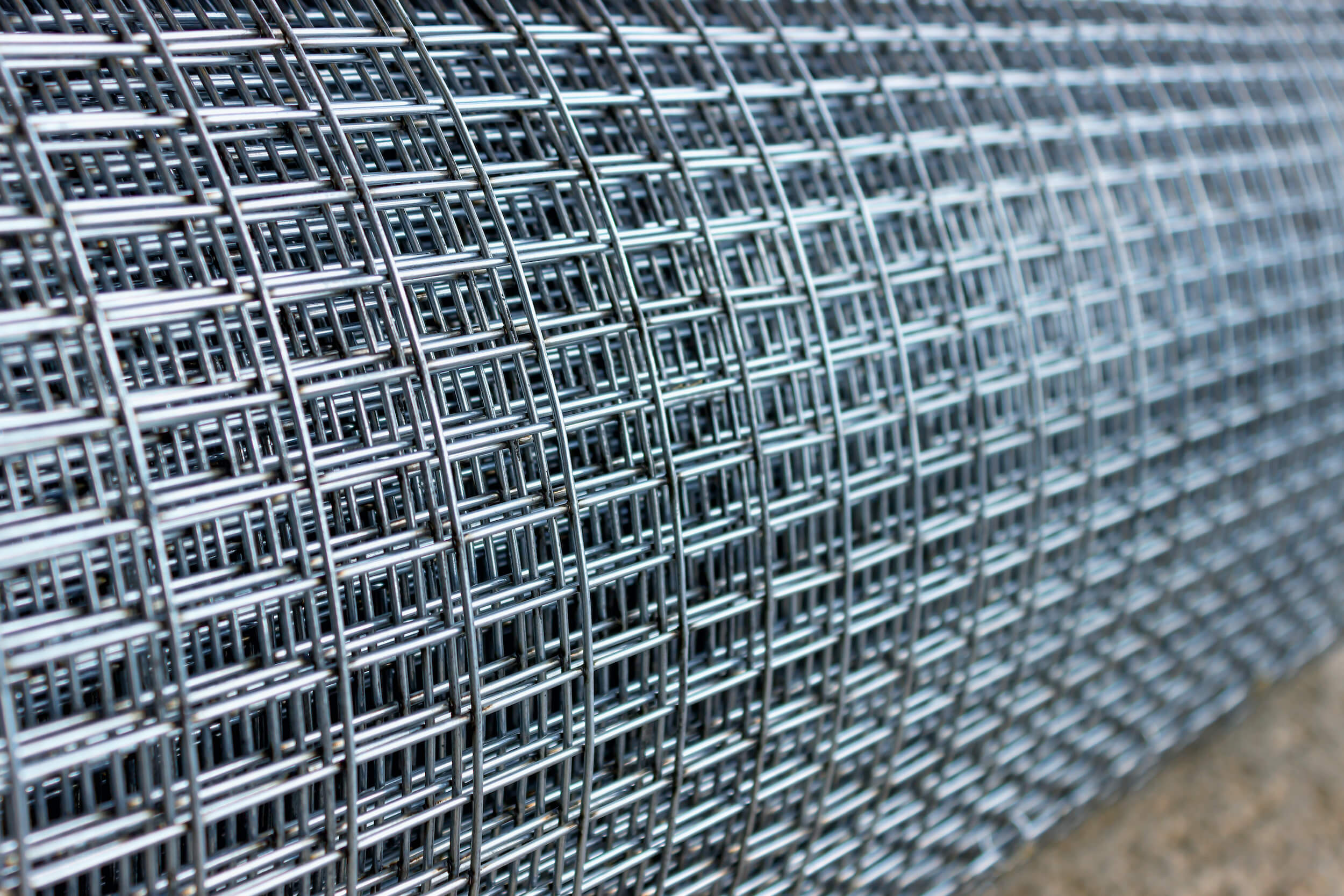

Welded wire mesh is a versatile and robust material, consisting of a grid of wires welded at their intersections, forming a stable and uniform structure. It is typically made from steel or stainless steel, ensuring high strength and durability, making it suitable for a wide range of applications. The mesh is available in various wire diameters and sizes, catering to different requirements and specifications. Its versatility is further highlighted by the ability to customize it into different shapes and sizes, allowing for its use in diverse contexts ranging from construction and industrial applications to agricultural and home uses. This adaptability, combined with its inherent strength, makes welded wire mesh a popular choice in many sectors.

Welded wire mesh is a versatile and robust material, consisting of a grid of wires welded at their intersections, forming a stable and uniform structure. It is typically made from steel or stainless steel, ensuring high strength and durability, making it suitable for a wide range of applications. The mesh is available in various wire diameters and sizes, catering to different requirements and specifications. Its versatility is further highlighted by the ability to customize it into different shapes and sizes, allowing for its use in diverse contexts ranging from construction and industrial applications to agricultural and home uses. This adaptability, combined with its inherent strength, makes welded wire mesh a popular choice in many sectors.

Types of Welded Wire Mesh

Welded wire mesh is offered in an array of sizes, wire diameters, and mesh patterns, making it a flexible material for various applications. It is commonly available in both sheets and rolls, with sizes ranging from smaller sheets, like 4' x 8', to larger rolls that can extend up to 5' x 150'. The wire diameters vary significantly, starting from as thin as 0.5 mm for lighter applications and going up to 12 mm for more heavy-duty uses. In terms of mesh patterns, square and rectangular configurations are the most prevalent, but the spacing between the wires can be adjusted to suit different uses. Additionally, custom mesh patterns can be created to meet unique project requirements. This versatility in size, diameter, and pattern allows welded wire mesh to be tailored to a wide range of project specifications and applications.

Welded Wire Mesh Material Specifications

Compliance with industry standards is a critical aspect of the production and use of welded wire mesh, ensuring its quality, strength, and suitability for various applications. In the United States, ASTM International sets the benchmark with standards like ASTM A185 for steel welded wire reinforcement and ASTM A497 for deformed steel welded wire reinforcement. On a global scale, the ISO (International Organization for Standardization) provides overarching standards, such as ISO 15630, which pertain to steel used in the reinforcement and prestressing of concrete. Additionally, local building codes in many regions play a pivotal role in determining the specific uses and specifications of welded wire mesh in construction projects. These standards are integral to maintaining consistency and safety in the use of welded wire mesh across different sectors and geographical locations.

Compliance with industry standards is a critical aspect of the production and use of welded wire mesh, ensuring its quality, strength, and suitability for various applications. In the United States, ASTM International sets the benchmark with standards like ASTM A185 for steel welded wire reinforcement and ASTM A497 for deformed steel welded wire reinforcement. On a global scale, the ISO (International Organization for Standardization) provides overarching standards, such as ISO 15630, which pertain to steel used in the reinforcement and prestressing of concrete. Additionally, local building codes in many regions play a pivotal role in determining the specific uses and specifications of welded wire mesh in construction projects. These standards are integral to maintaining consistency and safety in the use of welded wire mesh across different sectors and geographical locations.

Applications of Welded Wire Mesh

Welded wire mesh serves a variety of purposes across different sectors due to its strength, durability, and versatility. In the construction industry, it is commonly used for reinforcing concrete in slabs, walls, and floors, and is also utilized in building facades and partitions. Its industrial applications are diverse, including serving as protective machine guards, being integral to racks and storage units, and playing a crucial role in filtration and separation processes. In the agricultural sector, welded wire mesh is invaluable for fencing, providing protection for crops and containment for livestock, and is also used in creating support structures like trellises for plants. This wide range of uses across construction, industrial, and agricultural fields showcases the adaptability of welded wire mesh to meet specific needs and applications in different environments.

Customization of Welded Wire Mesh

Welded wire mesh offers a high degree of customization in terms of sizes and shapes to cater to specific project requirements. Typically, it is available in both sheets and rolls, with standard sheet sizes like 4' x 8', and varying roll sizes, for instance, 5' x 150'. Regarding shapes, the mesh is primarily available in rectangular or square configurations, with the option to adjust the spacing between the wires to suit particular needs. This flexibility in customization allows for the production of welded wire mesh in custom sizes and shapes, making it an ideal solution for a wide range of applications that require specific dimensions and forms. Such adaptability ensures that welded wire mesh can be effectively integrated into diverse projects, from construction and industrial applications to customized design projects.

Welded wire mesh offers a high degree of customization in terms of sizes and shapes to cater to specific project requirements. Typically, it is available in both sheets and rolls, with standard sheet sizes like 4' x 8', and varying roll sizes, for instance, 5' x 150'. Regarding shapes, the mesh is primarily available in rectangular or square configurations, with the option to adjust the spacing between the wires to suit particular needs. This flexibility in customization allows for the production of welded wire mesh in custom sizes and shapes, making it an ideal solution for a wide range of applications that require specific dimensions and forms. Such adaptability ensures that welded wire mesh can be effectively integrated into diverse projects, from construction and industrial applications to customized design projects.

FAQs

Ordering Process

- Include information on how to order, minimum quantities